Aluminum is one of the most abundant metals in the earth’s crust.

Aluminum has a silvery-white color, light weight and high electrical conductivity. The metal melts at a temperature of 660 °C. Among the advantages noted are low density, fairly high strength, excellent heat conductivity, and corrosion resistance.

Due to this, it is considered one of the most important technical metals. Aluminum alloys are obtained by casting, wrought and other methods.

Being in nature

One of the most common metals is aluminum. It occupies 8.8% of the entire mass of the earth’s crust. Its compounds are bauxite, aluminosilicates, corundum. Most of the earth’s crust is made up of aluminosilicates. Bauxite is one of the rocks from which aluminum is extracted.

Almost all aluminum metal in nature is found only in compounds. In rare cases, pure metallic aluminum is found in very small quantities. Among the main connections it is worth noting the following:

- Bauxites;

- Nephelines;

- Alunites;

- Alumina;

- Corundum;

- Feldspars;

- Kaolinite;

- Beryl;

- Chrysoberyl

It is also found in natural waters in the form of low toxicity compounds such as fluoride. Pure aluminum contains only the stable isotope 27 AI.

How aluminum is obtained

The chemical element aluminum is quite difficult to obtain in its pure form. To obtain aluminum, it will be necessary to carry out many steps to separate it from other elements. How is aluminum obtained?

The process itself consists of several stages: grinding of bauxite ore and extraction of alumina, obtaining the final element from it. In other words, it is called crystalline alumina, which is electrolyzed in cryolite. Melting point 960 – 970 °C. This procedure requires a large amount of electricity, so the production of the substance is often located near large-scale power plants.

Where and how is aluminum produced

The extraction and production of aluminum generally consists of three stages. The first and second stages are the production of bauxites and the formation of alumina from them. At the latter, a pure material is obtained from alumina in the process of electrolysis. For 4-5 tons of aluminum-containing ore, there are 2 alumina and 1 aluminum.

Aluminum mining in the world can be made from other aluminum ores, but bauxite is considered the most common. Their basis is aluminum oxide and other minerals. The quality is determined by the high metal content. The total world stock of aluminum ores is more than 18 billion tons. Given the current production of aluminum in the world by country, it should be enough for more than one century.

Most of the bauxites are found in countries with a tropical belt. Only 73% is in India, Guinea and Australia. Most bauxites are concentrated in Guinea. They have high quality and a minimum of mineral impurities. According to estimates in 2014, such countries are noted as leaders in aluminum production: China, Australia, Brazil, Guinea, India, Jamaica, Russia and Kazakhstan.

As a rule, aluminum mining is carried out by an open method. With the help of special equipment, a layer of the earth’s crust is removed, which is transported for the next stage of processing. There are deep ore mining points. To get it, you have to build mines. The deepest mine is in Russia. Its depth is 1550 meters.

Russia is on the 7th place in the world ranking in terms of aluminum production. There are more than fifty deposits in this country. One of the oldest is considered Radynskoye, located in the Leningrad region. Among all aluminum mining sites in Russia, there are Little Red Riding Hood, Kalinskoye, Novo-Kalinskoye in Severouralsk, and Cheremuzovskoye in the Sverdlovsk Region. Our country is also famous for a wide variety of metal manufacturing plants. The largest in Russia and not only is Rusal, which produces more than 3 million tons of metal.

Physical and chemical properties

The main physical properties of aluminum are high thermal conductivity, almost twice that of steel. In addition, it has a density three times less than that of iron and zinc. And to all this it is worth adding the high strength of the material. Aluminum reacts with such substances: copper, magnesium, silicon and others.

Chemical properties of aluminum:

- Formation of ionic and covalent compounds;

- High ionization energy;

- High charge density along with cations of other similar materials;

- Low susceptibility to corrosion;

- Reaction with oxygen, halogens, non-metals, fluorine, sulfur, nitrogen, carbon, water.

Metal applications

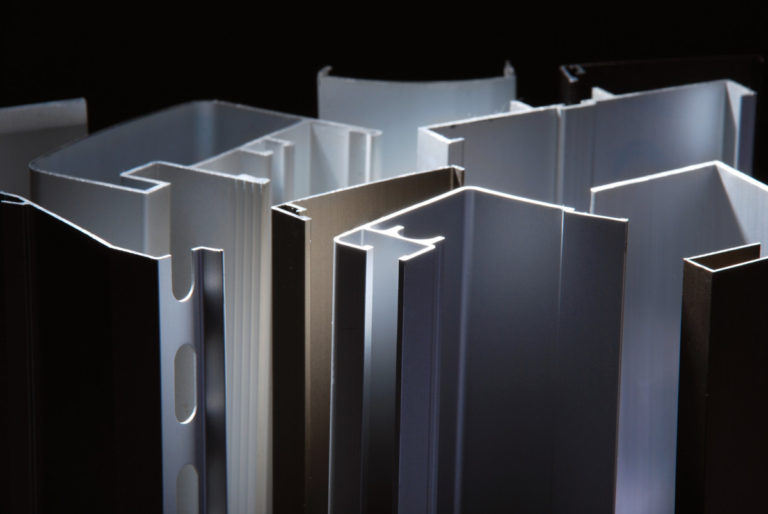

Aluminum has been widely used as a structural material. Its main advantages are light weight, stamping flexibility, corrosion resistance, a high level of thermal or electrical conductivity, and non-toxic compounds. It is these advantages that have led to its widespread use in the production of kitchen utensils, packaging containers and foil for the food industry.

Speaking about the shortcomings, we should first of all note the low strength. Therefore, a small proportion of copper and magnesium was added to aluminum. Also, the material is successfully used in the manufacture of electrical engineering, since its electrical conductivity is at a high level. The only negative is the difficulty of soldering due to the strong oxide film.

Light metal is used in various types of transport. In the field of aviation, it is the main structural material. The use of aluminum also affected the shipbuilding industry. With the help of alloys, hulls, decks and equipment for ships are produced from it.

Application as a reducing agent

Aluminum has been successfully used as a reducing agent. Aluminum recovery of metals is quite common. Smelting aluminum allows you to restore rare types of metals. It is also used for pyrotechnics.

Types of alloys

For the production of structural materials, greater strength is required. Aluminum does not possess such, therefore it is combined with other chemical elements in a smaller amount. The most common alloys:

- Aluminum-magnesium. They are characterized by high strength, flexibility, corrosion resistance, vibration resistance and weldability. The percentage of magnesium in alloys is no more than 6%.

- Aluminum-manganese. They also have high strength, ductility, corrosion resistance and weldability.

- Aluminum-copper. One of the most high tech. An improved version of low carbon steels. A significant disadvantage is susceptibility to corrosion.

Aluminum in jewelry

Metal was of particular value during the time of Napoleon III. At that time, jewelry, buttons, dishes were made from it. She was evaluated along with gold and silver. But the demand for aluminum jewelery faded quickly as new mining opportunities arose.

Other applications

Light metal is used in various industries, including the military industry. This usually applies to weapons production. Also known is its use in rocket technology as a solid propellant and combustible components.

Metal toxicity

Although aluminum is very common in the world, living things do not use it due to its low toxicity. Its compounds for a long time have a harmful effect on people and animals. Acetate and aluminum hydroxide have the greatest influence. They have a negative effect on the nervous system and the excretory function of the body.

Interesting facts about aluminum

This metal has the following features:

- Its compounds exist not only on our planet, but also on the Moon and Mars;

- The human body has more than 100 mg of this substance;

- The daily requirement for it is 2.4 mg;

- Most of the chemical element is found in apples;

- The first bar of pure metal was produced in 1932.